RO and Desalination Plant

Small Scale Desalination and Industrial Reverse Osmosis Systems

In the realm of water and wastewater treatment, small-scale desalination and industrial reverse osmosis (RO) systems have emerged as transformative solutions. These technologies offer exceptional efficiency and reliability, catering to diverse applications. This article explores the unique features and advantages of small-scale desalination and industrial RO systems, emphasizing their role in addressing the global water treatment challenge.

Small Scale Desalination

Currently, the mainstream desalination systems primarily comprise large-scale centralized seawater desalination plants. However, small-scale desalination equipment, especially those with daily capacities below 5000m³, continues to grapple with pre-treatment challenges. Our package and design-based systems excel in their adaptability and efficiency for handling pre-treatment processes and overall equipment for such scale, making them a remarkable solution.

Small-scale desalination systems have revolutionized the way we address water scarcity, providing sustainable solutions for regions facing freshwater shortages. These systems are designed to efficiently convert seawater into fresh, potable water, and are particularly well-suited for compact communities, islands, and areas with limited water resources.

Advantages of Small Desalination Systems: Small-scale desalination systems offer numerous benefits, including:

- Direct connection to raw seawater

- Package integrated pre-treatment and unmanned outdoor operation

- Cost-Efficiency: cost-effective, making desalinated water accessible even in resource-constrained areas.

- Sustainability: Reducing the environmental impact of water scarcity by tapping into seawater resources.

- Package Plant Design: Modular and package plant design allows for easy installation and maintenance.

- High Water Recovery: Advanced technologies enable high water recovery rates, minimizing wastage.

Industrial Reverse Osmosis (RO) Systems

Industrial RO systems are at the forefront of water treatment technology, delivering high-quality water purification for various industries. They are renowned for their ability to remove impurities, dissolved solids, and contaminants from water, making them essential for processes that demand ultra-pure water.

Benefits of Industrial Reverse Osmosis Systems: Industrial RO systems are favored for their:

- Exceptional Water Purity: They ensure that water used in industrial processes meets stringent quality standards.

- Reduced Operating Costs: Their efficient filtration results in cost savings and minimal environmental impact.

- Tailored Solutions: Customizable to specific industrial needs, RO systems adapt to varying water sources.

Key Applications

Industrial Reverse Osmosis (RO) Systems are instrumental in various applications, including:

- Municipal water and wastewater treatment

- Industrial water and wastewater treatment

- Treating impaired water sources

We provide a reliable source of clean water for both large-scale industries and small communities. Leading water and wastewater treatment companies play a pivotal role in developing and implementing small-scale desalination and industrial RO systems. Our expertise and commitment to innovation drive the advancement of water treatment technologies.

System Advantages:

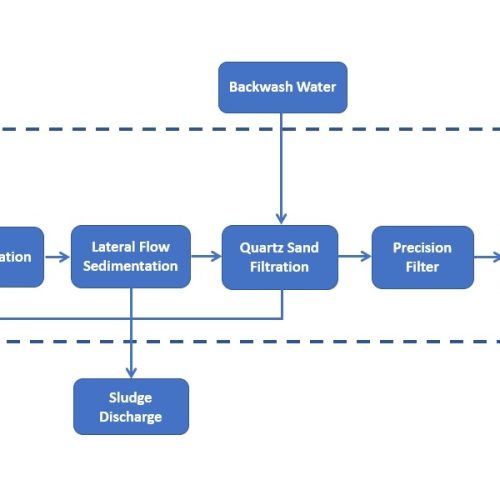

Enhanced Stability: While conventional two-stage pretreatment systems can handle most situations, they face increased backwash pressure and membrane damage risks when influent water quality fluctuates. Typical two-stage membrane treatment systems can handle influent water with turbidity levels of around 50 NTU, whereas our WaterEazy Water Plant can accommodate influent water with turbidity levels of <1000 NTU.

Extended Lifespan of Membrane Components and Consumables, Cost Savings: Through the lateral flow process, the influent water quality before entering the membrane system is around 1 NTU. Higher water quality conditions can significantly extend the working lifespan of membrane treatment systems by 20% to 50%.

Reduced Backwash Water Consumption: WaterEazy Water Plant’s pretreatment system consumes less than 1% of the influent water volume for backwashing.

Our remarkable innovation capabilities have endowed our membrane and desalination systems with superior stability, cost-effectiveness, and efficiency. This has allowed us to integrate complete membrane treatment or seawater desalination systems into a single container, making it the optimal choice, especially in scenarios with high turbidity or significant water contamination. At WaterEazy, we are dedicated to delivering cutting-edge solutions that ensure access to clean, reliable water while minimizing operational costs and environmental impact. With our technology, we turn water challenges into opportunities, providing sustainable and efficient water treatment solutions for a variety of applications.

Small-scale desalination and industrial RO systems offer sustainable, cost-effective solutions for addressing the pressing global water treatment challenge. These technologies, made possible by the dedication and innovation of water and wastewater treatment companies, ensure access to clean and reliable water sources, regardless of the scale or location.

| Features | WaterEazy Water Plant's Coagulation + Sedimentation Membrane Treatment System | Conventional Sand Filtration + Activated Carbon Filtration Membrane System |

|---|---|---|

| Inlet Water Turbidity | <1000 | <50 |

| Inlet Water Quality | Ground or Surface Water | Tap Water |

| Turbidity Before Entrance of Membrane | <1 | <5 |

| Conductivity | Same | Same |

| Backwash Cycle | Longer (1-2days) | Shorter |

| Membrane Module Lifespan | 20% - 50% longer | Lower |

| Operation Condition | Automatic Intelligence/Unmanned/Remote Control & Monitoring | Based on Software and Accessories |

| Operation Environment | Outdoor and Indoor | Require Indoor Operation |

Latest News & Article

On November 18, 2022, Watereazy’s Wangshan Water Treatment Plant, located in the Xihai’an New Area of Qingdao, Shandong Province, marked its official 10th anniversary since

Hotone (Watereazy) pioneers an innovative 3D ecological wastewater treatment tower, revolutionizing conventional sewage plants into odorless, compact, and environmentally sustainable facilities.

On June 10th, 2022, Watereazy’s Intelligent Manufacturing Center held a momentous event marking the completion and dispatch of their cutting-edge modular package water plant powered

Explore Lingyuan Project: Innovative package water plant initiative, promising efficient water treatment and supply solutions

Membrane treatment and seawater desalination have become highly prevalent technologies in the water treatment industry. Compared to traditional dual-filtration membrane systems, our membrane-integrated solutions offer superior performance in certain aspects. Our innovative approach to membrane systems sets us apart in the field.

Innovative Coagulation and Sedimentation Integration: With incorporation of coagulation and sedimentation components, our new system offering multi-faceted enhancements over traditional dual-filtration membrane systems:

- Enhanced Adaptability to Varying Water Qualities: Our new system ensures that the influent turbidity (measured in NTU) remains below 5, even when the raw water turbidity doesn’t exceed 1000 NTU. This broadens the system’s adaptability to diverse water qualities. Classic dual-filtration systems typically demand influent turbidity below 50 NTU.

- Extended Lifespan and Increased Output:

- The integration of coagulation and sedimentation components significantly extends the replacement intervals of membrane systems, reducing costs.

- Additionally, the extremely low turbidity achieved through sedimentation substantially reduces the water volume required for backwashing, thereby enhancing overall water output.

Our exceptional coagulation and sedimentation system performance offers a diverse range of applications within integrated equipment. Seamlessly interfacing with various membrane processing systems, including seawater desalination, this outstanding capability forms the foundation for providing solutions across multiple purposes. If your requirements align with these capabilities, please don’t hesitate to reach out to us.

Social Media Posts

This is a gallery to showcase images from your recent social posts